| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : DINGSCO

Model Number : According to customers' requests

Certification : ISO 9001

Place of Origin : Changsha, China

MOQ : Negotiable

Price : Negotiable

Payment Terms : T/T

Supply Ability : Negotiable

Delivery Time : (Sample order) 7 days

Packaging Details : According to customers' requests

Applicaion : Agricultural, Machinery and Industry

Material : 20CrMnTi/20CrMo/20CrNiMo/18CrNiMo/38CrMoAl/42CrMo/40Cr/45#......

Teeth Profile : Gleason

Toothed Portion Shape : Bevel Wheel

Heat Treatment : Carburization and quenching/Carbonitriding/High frequency/Quenched and tempered......

Manufacturing Method : Grinding

Large module gears refer to gears with a larger module. The module is a basic parameter in gear design, which defines the size of the gear teeth. The larger the module, the larger the teeth of the gear, and the gear itself will be larger and stronger. Here are some of the main features of large module gears:

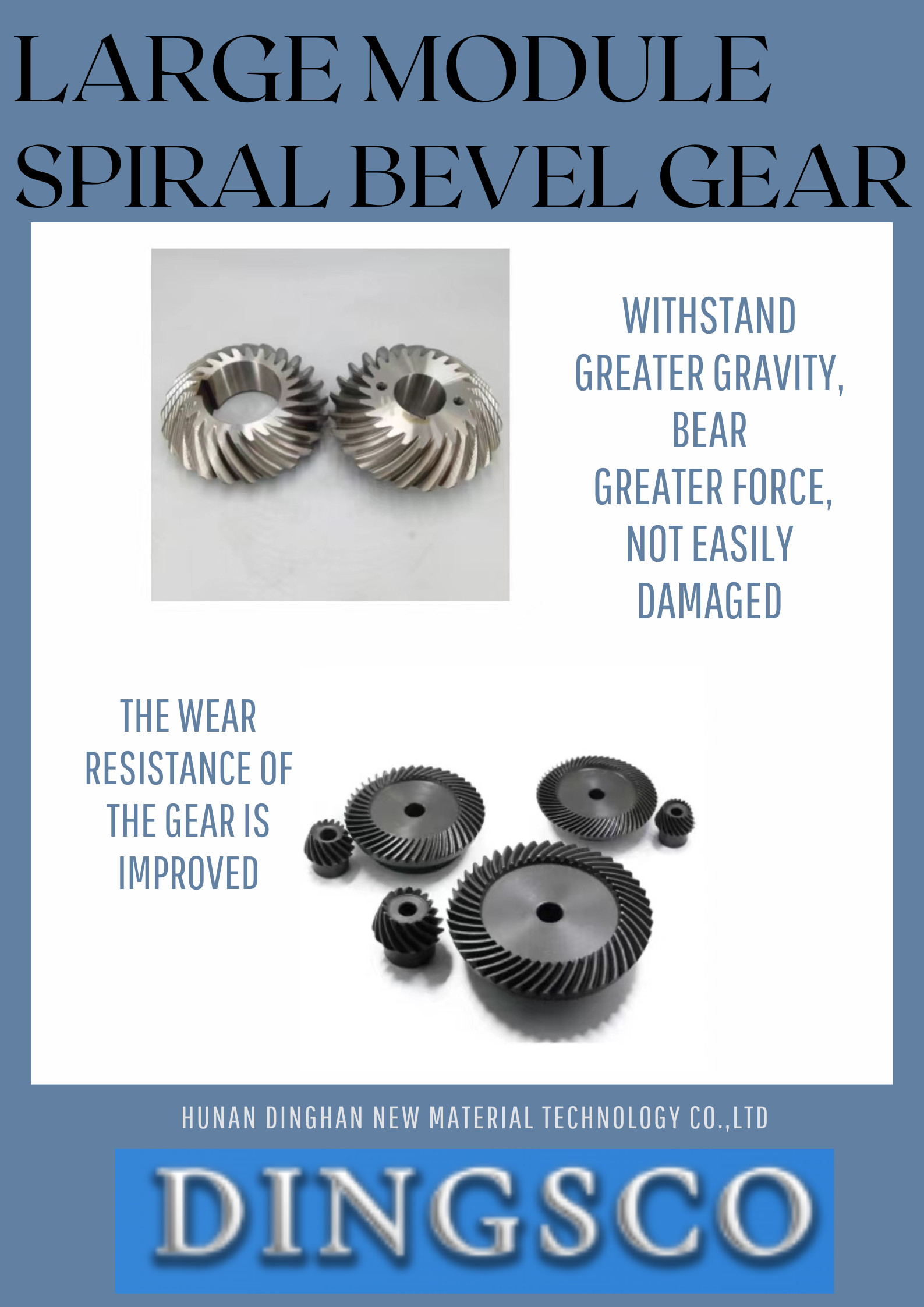

| Product | Large Module Spiral Bevel Gear |

|---|---|

| Gear Position | External Gear |

| Module(M) | 0.5 - 30 M |

| Teeth Accuracy Grade | ISO 7-6 Grade |

| Service | Customized |

| Hardness | Hardened Tooth Surface |

|

|

Large Module Spiral Bevel Gear High Quality Forging Large Crown Wheel Pinion Professional Manufacturer Images |