What are the characteristics of robot gears?

Robot gears: require lightweight, large transmission ratio, and high precision.

1) Lightweight. The power of the motor is limited. Only the lighter the weight of the robot, the more effective work can be done. This requires the gears to be light in weight and small in number. Usually there are only 2-stage transmission or 3-stage transmission. Humanoid robots have many joints, many parts, and low power, so they have higher requirements for lightweight gears.

2) The transmission speed ratio is large. Due to the high speed of the motor and the low speed of the robot's joints, a large deceleration transmission is required between the motor and the robot's joint output. Coupled with the restriction of lightweight, the gear single-stage transmission has a large transmission ratio and a small number of pinion teeth to reduce the volume of the entire gear system.

3) High accuracy. The robot actuator is at the end, and the extremely small accuracy error of the reducer will be amplified dozens of times at the end, so the robot has very high accuracy requirements for each joint reducer.

Why choose us?

1.Internationally, power transmission gear devices are developing in the direction of miniaturization, high speed, and standardization. We are experts dedicated to high-quality small module gears. Our factory was founded in 1994 and has 30 years of industry experience.

2.Our company currently has one doctorate (member of the China Gear Standardization Technical Committee) and one graduate student engaged in bevel gear research. We have a complete set of software for digital closed-loop manufacturing of spiral bevel gears, specializing in gear R&D, design, strength verification and high-precision gear manufacturing.

3.Our company has a complete set of advanced production equipment and testing equipment such as multiple CNC 7-axis 5-linkage spiral bevel gear grinding and gear milling machines. It has successively developed high-quality products for users such as high reduction ratio, high speed, heavy load, low noise, and low number of teeth, which can meet the high-quality gear needs of industries such as reducers, industrial robots, industrial sewing machines, and model aircraft.

| Spiral Bevel Pinion Gear Long Life Grinding Gear for Robot Joint |

| Specification |

| Material | 20CrMnTi,42CrMo, 45# etc | Surface | Bright |

| Shape | Spiral | Pressure Angle | 20°, also can be customized |

| Tooth Profile | Gleason Type | Accuracy Grade | ISO 6-7 Grade |

| Processing | Grinding | Module (M) | ≤4 |

| Heat Treatment | Carburizing, quenching, carbonitriding, high-frequency, quenching, tempering etc. | Application | Robot joint |

Advanced manufacturing equipment

DH has multiple CNC 7-axis 5-linkage spiral bevel gear grinding machines and gear milling machines that can process high-reduction ratio hypoid and transverse cured tooth coupling.

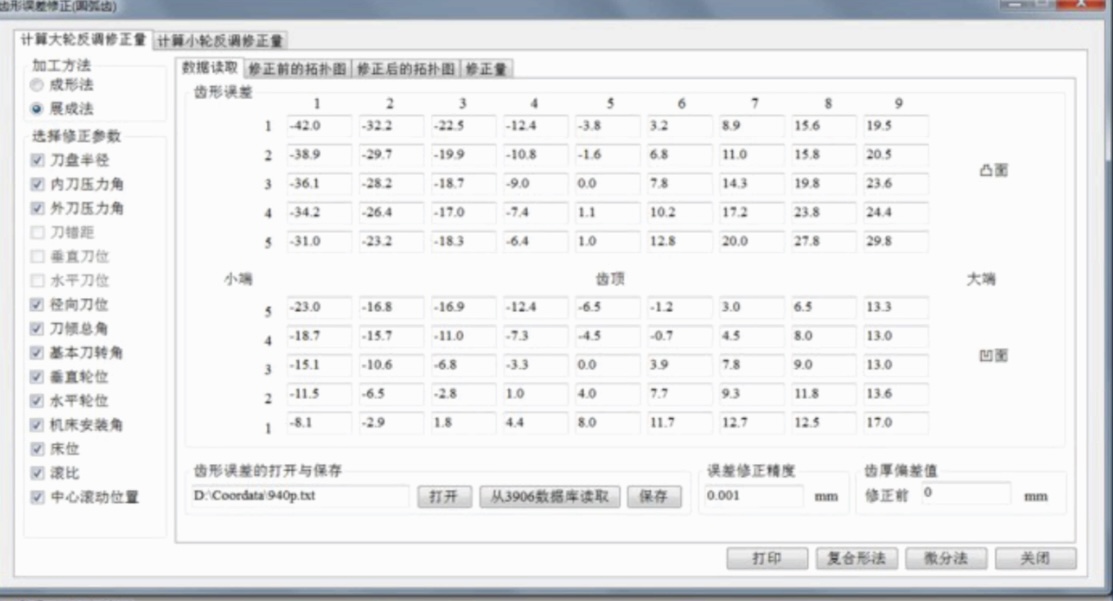

Advanced testing equipment

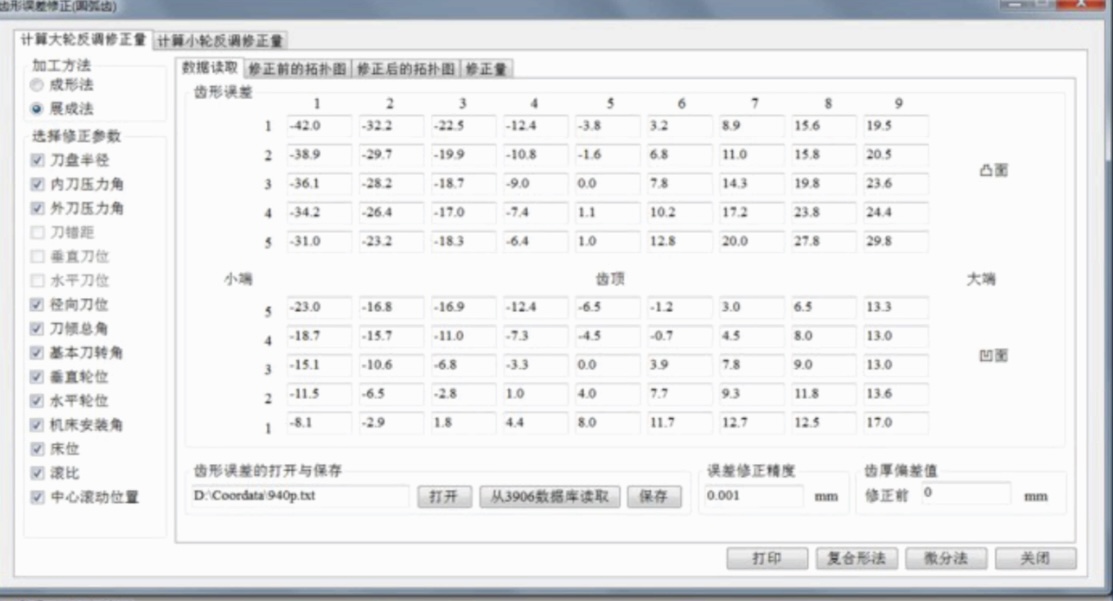

Utilize a high-precision gear measurement center to complete gear pitch accuracy detection, tooth profile error detection and inverse correction of tooth profile errors.

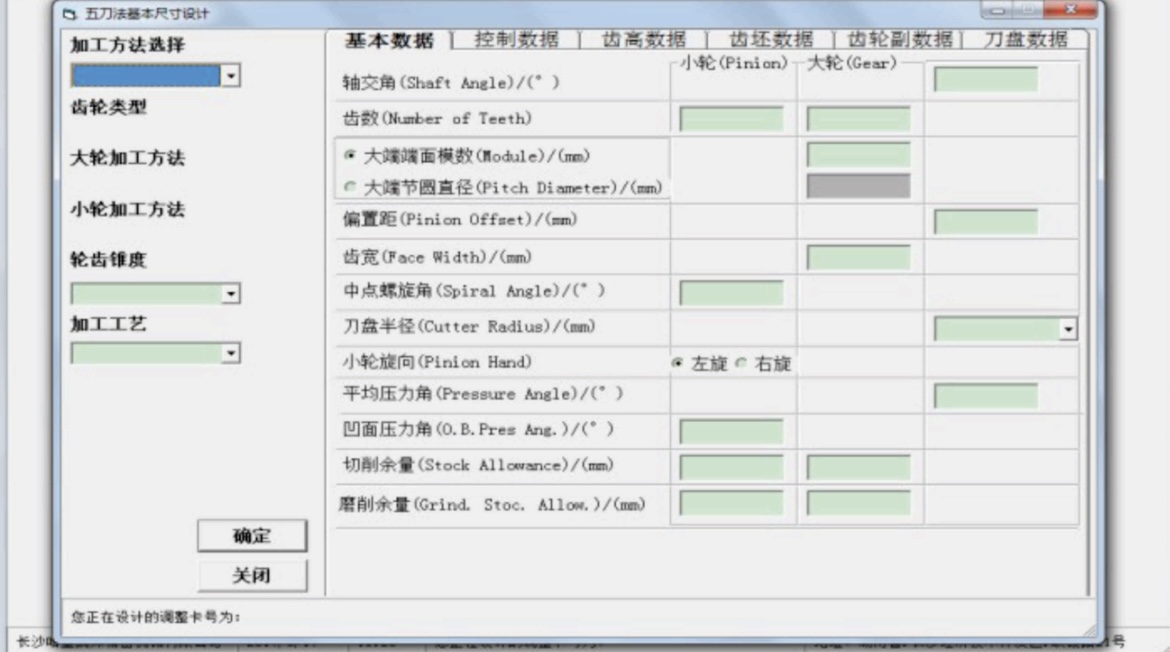

Professional software

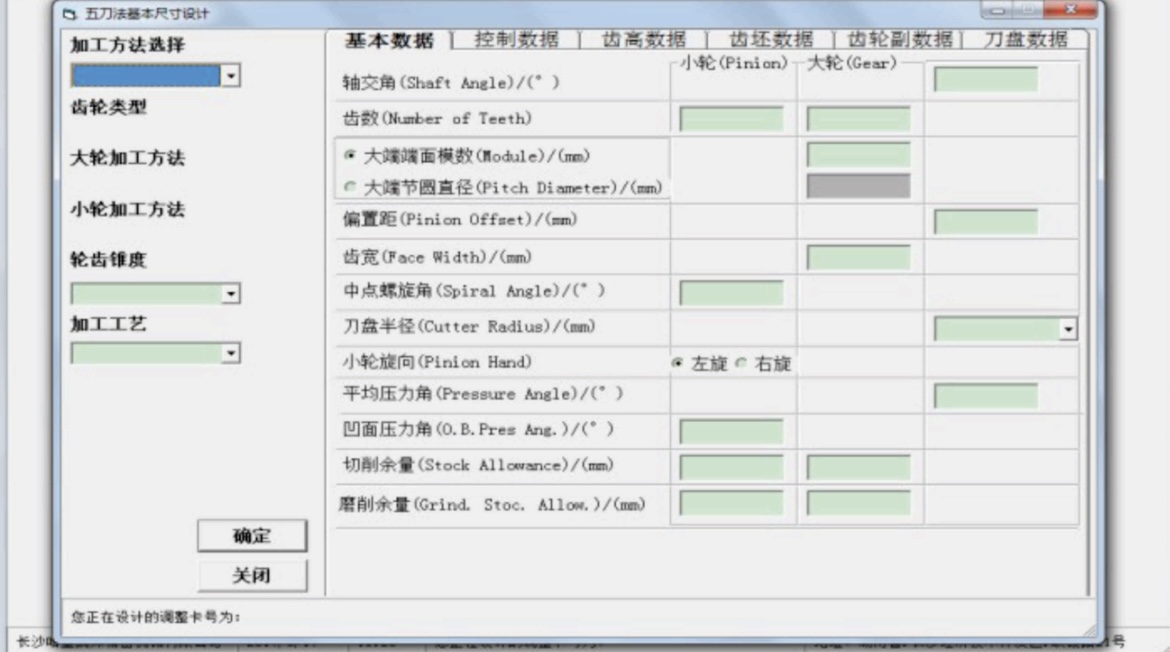

Our factory has a complete set of software to realize digital closed-loop manufacturing of spiral bevel gears, Functions such as gear design, strength calculation, contact analysis, tool calculation, tooth profile error reversal, etc. can be realized. Machining methods include five tools machining(fixed setting) & G-plete of tapper , spiral format tilt(SFT) method & hypoid format tilt (HFT) method of Cycloid equidep, etc.

Product Tags:

|

|

Spiral Bevel Gear Pinion Grinding Gear Process For Robot Joint Images

|